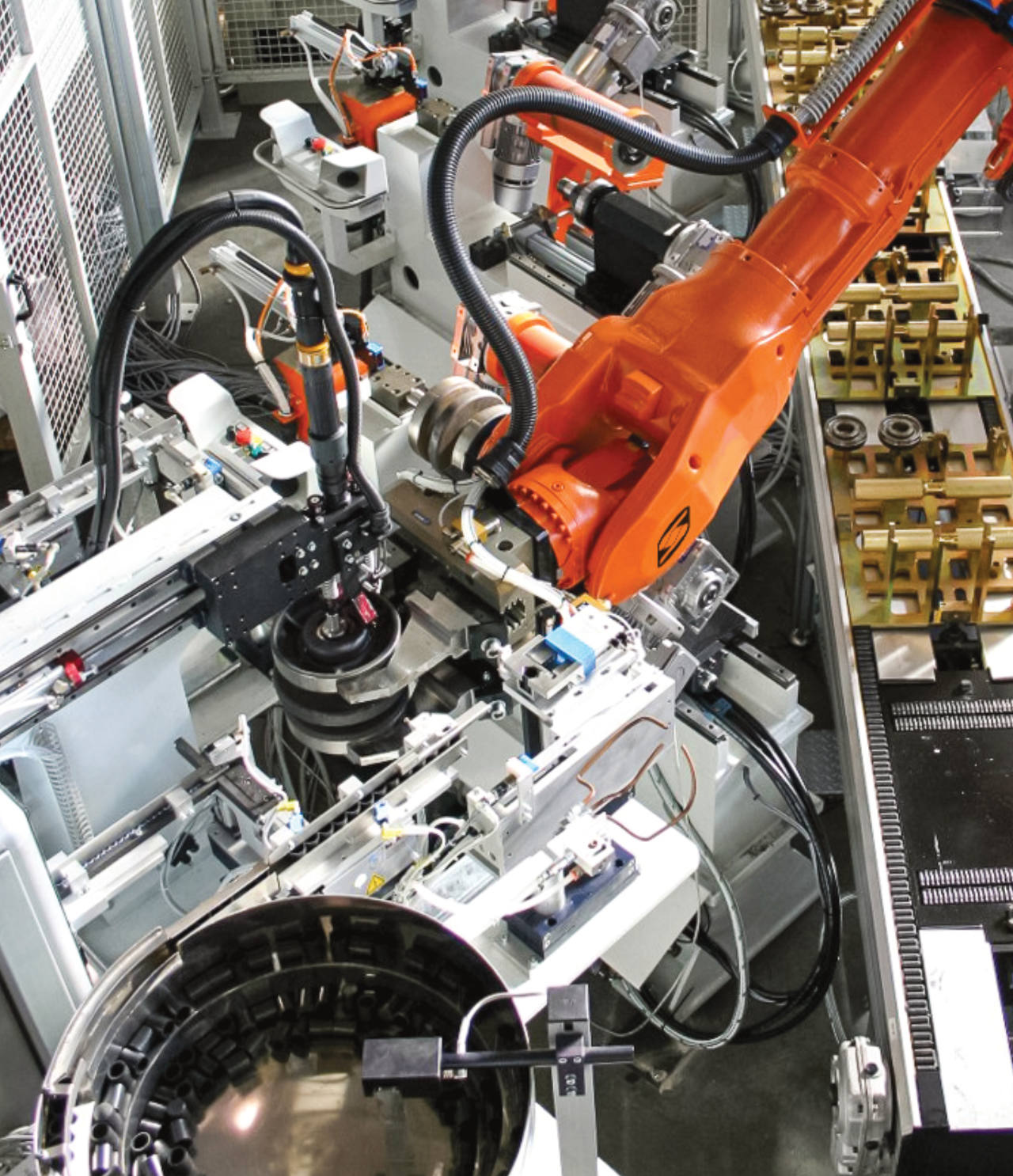

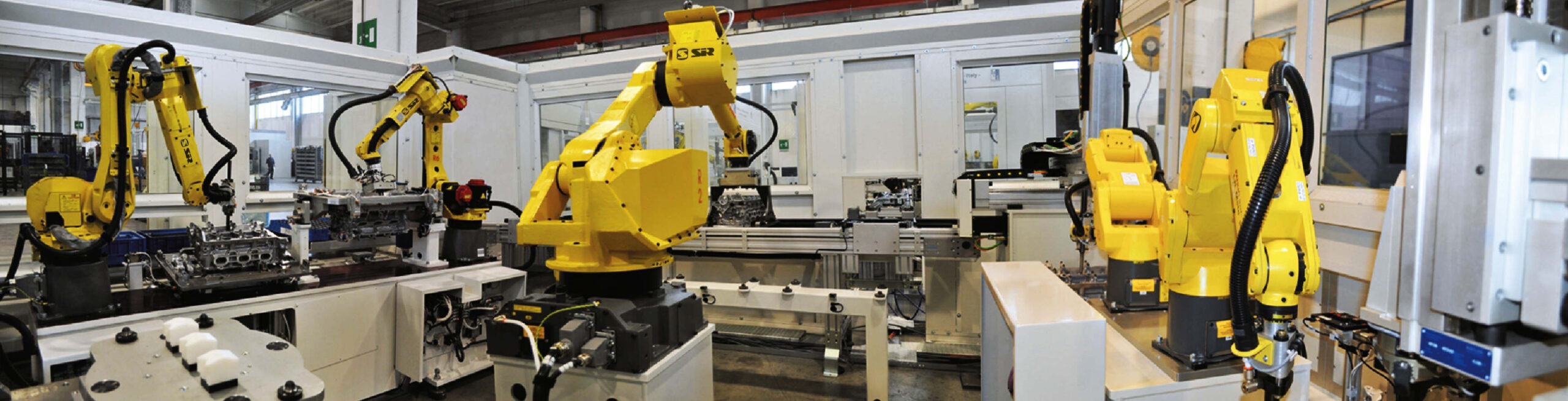

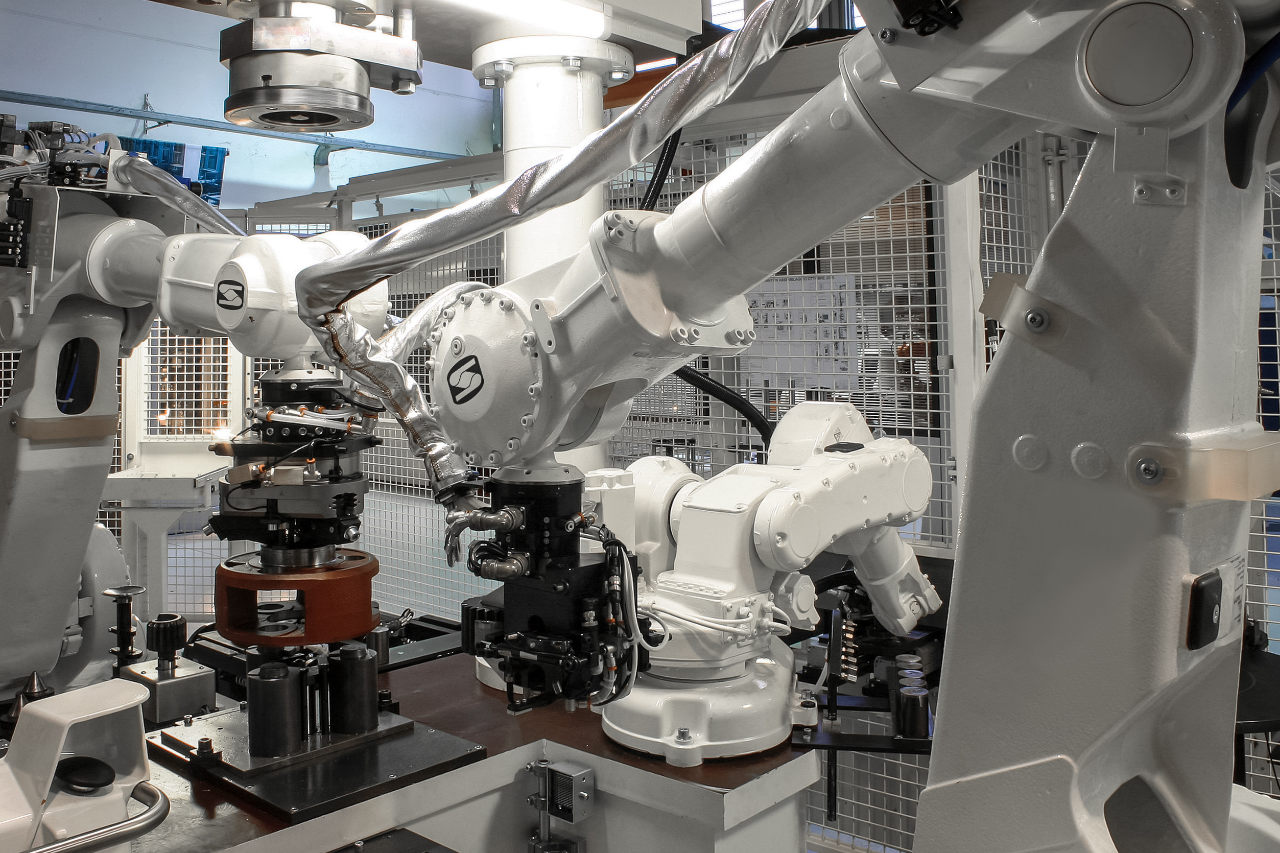

ASSEMBLY

We create assembly custom lines to guarantee efficient, top quality production from the infeed of components through to palletisation of the finished product.

FUNCTIONAL INTEGRATION

We build robots and mechanisms that interact to share information and balance the workload, to assemble any type of product.

QUALITY AND EFFICIENCY

SIR solutions deliver drastic reductions in production times with impressive increases in quality. All with efficiency over 90%.

FLEXIBILITY

SIR lines’ automatic retooling opens the way to randomised production and automation that leaves behind the rigidities of the past in progression to the one-piece batch.

FUNCTIONAL CHARACTERISTICS

Randomised production and automatic retooling

Production traceability

Optical inspection and functional testing of the finished product.

APPLICATION AREAS

Automotive

Aeronautica

Mechanical

Electromechanical

SOLUTION EXAMPLES

- Powertrain components mounting.

- Tight interference fit.

- Electric motors mounting.

- Aviation engine components mounting.

- Automotive chassis assembly.

- Earth-moving equipment components assembly.

- Gearmotors mounting.

- Box beams screwing-mounting and riveting.

- Assembly of mechanical components.

- Assembly of electrical components.

VIDEO

DOWNLOAD THE BROCHURE

To download the complete brochure of SIR Assembly solutions, enter your data and click “SEND”: you will receive an email with a link to download the PDF file at the address you provided within a few minutes.