HANDLING

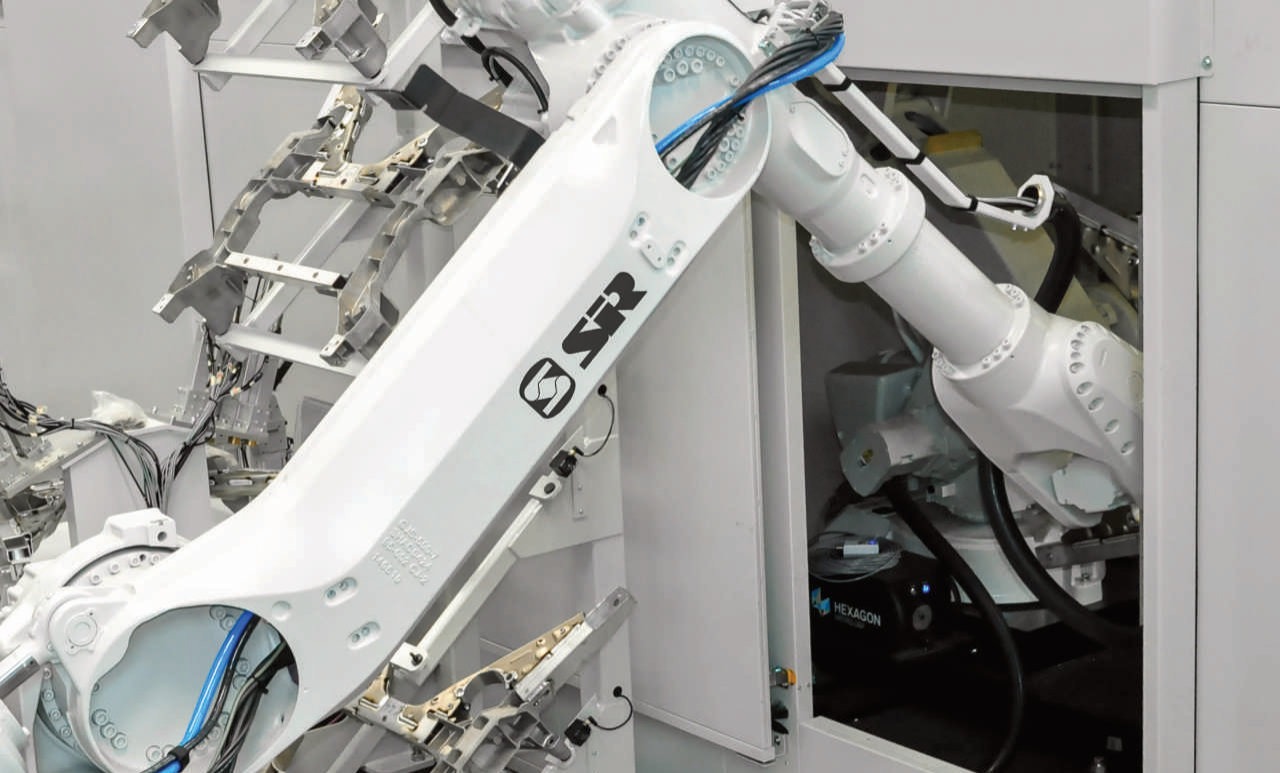

SIR reinvents conventional machine tool tending by creating multi-function lines that combine traditional handling with a vast assortment of secondary procedures.

HIGH PRODUCTION RATES

SIR manipulation systems guarantee speed and efficiency: equipped with the best traditional or collaborative robots on the market, they have specific grippers and mechanical systems, with solutions ranging from the single unit to sequential tending lines.

UNIVERSAL FEEDING

2D and 3D artificial vision with bin-picking capability allows the use of universal feeding systems, requiring no retooling between batches, with impressive simplification of industrial logistics.

QUALITY CONTROL

Using the robot as optic sensor positioner, manipulation lines can be equipped with inspection systems that can objectively assess processed product quality through surface, dimensional or assembly checks.

FUNCTIONAL CHARACTERISTICS

Feeding guided by Vision Systems

Dedicated Grippers

Functional Integration

Automatic Product Inspection

APPLICATION AREAS

Automotive

Mechanical

Electromechanical

SOLUTION EXAMPLES

- Machine tool tending with articulated robots.

- Machine tool tending with Cartesian manipulators.

- Bin picking with 2D and 3D vision systems.

- Robotics industrial automation.

- Finished product and components inspection.

- Collaborative robot manipulation systems.

VIDEO

DOWNLOAD THE BROCHURE

To download the complete brochure of SIR Handling solutions, enter your data and click “SEND”: you will receive an email with the link to download the PDF file at the address you provided within a few minutes.