WELDING

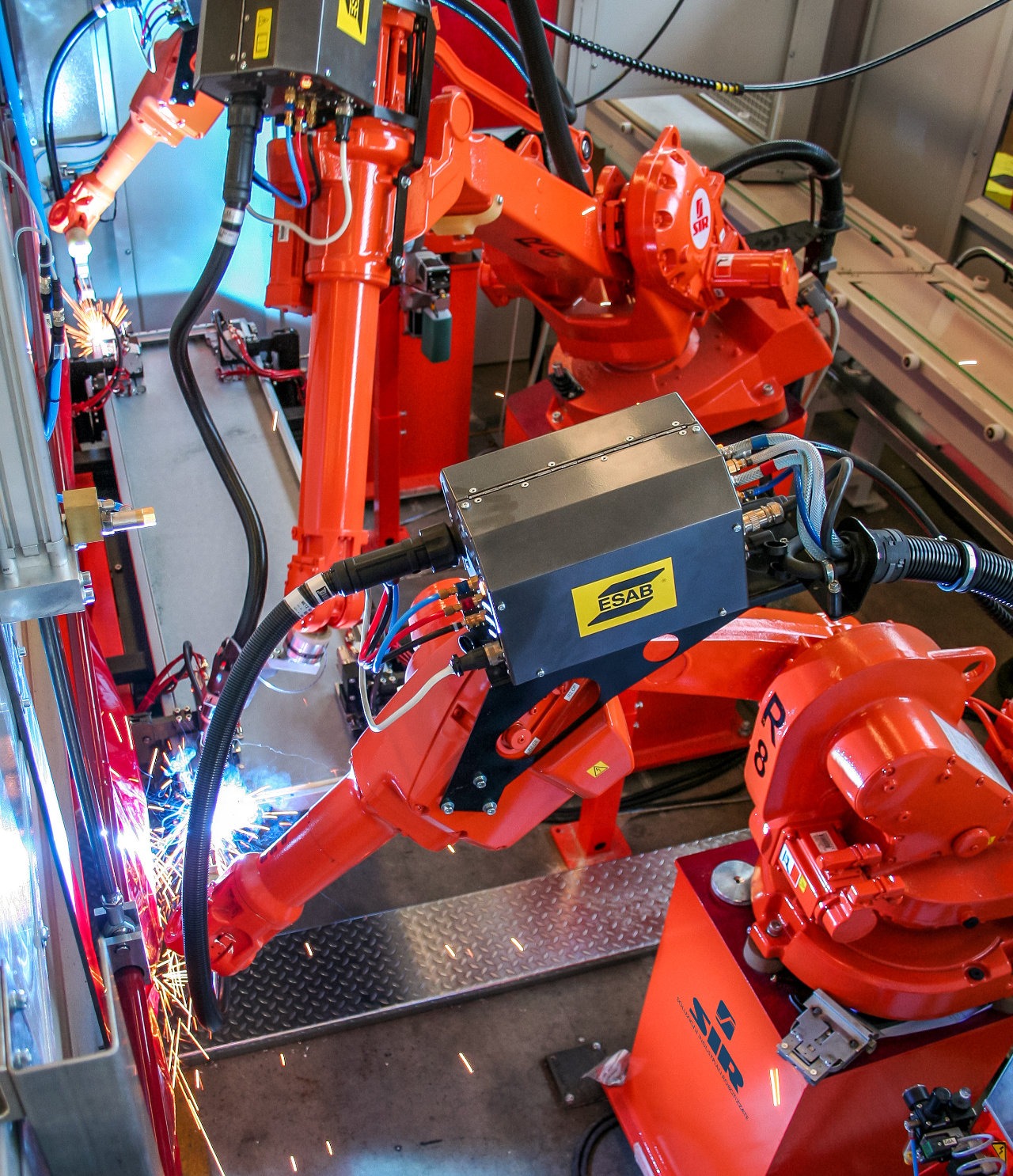

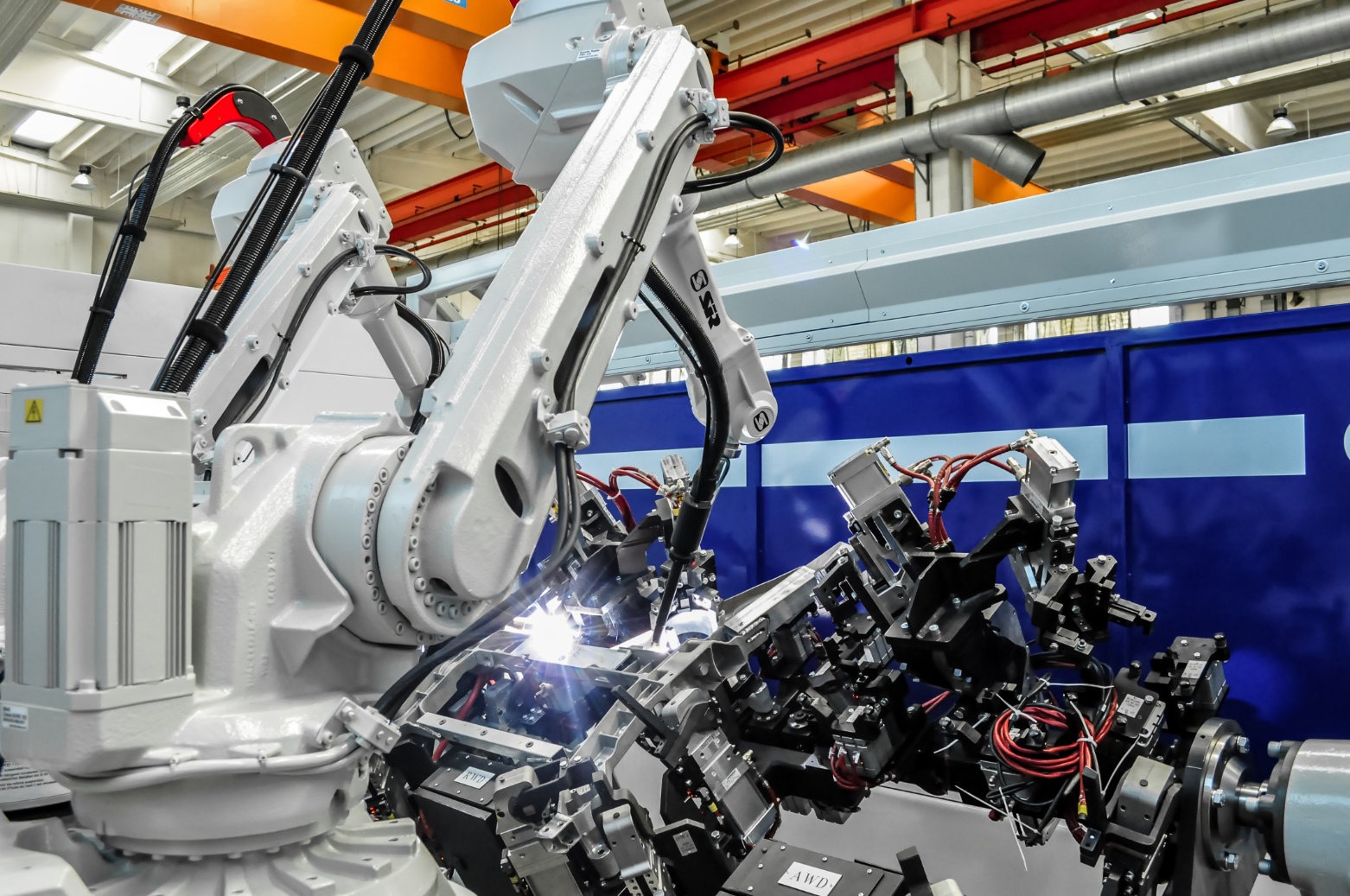

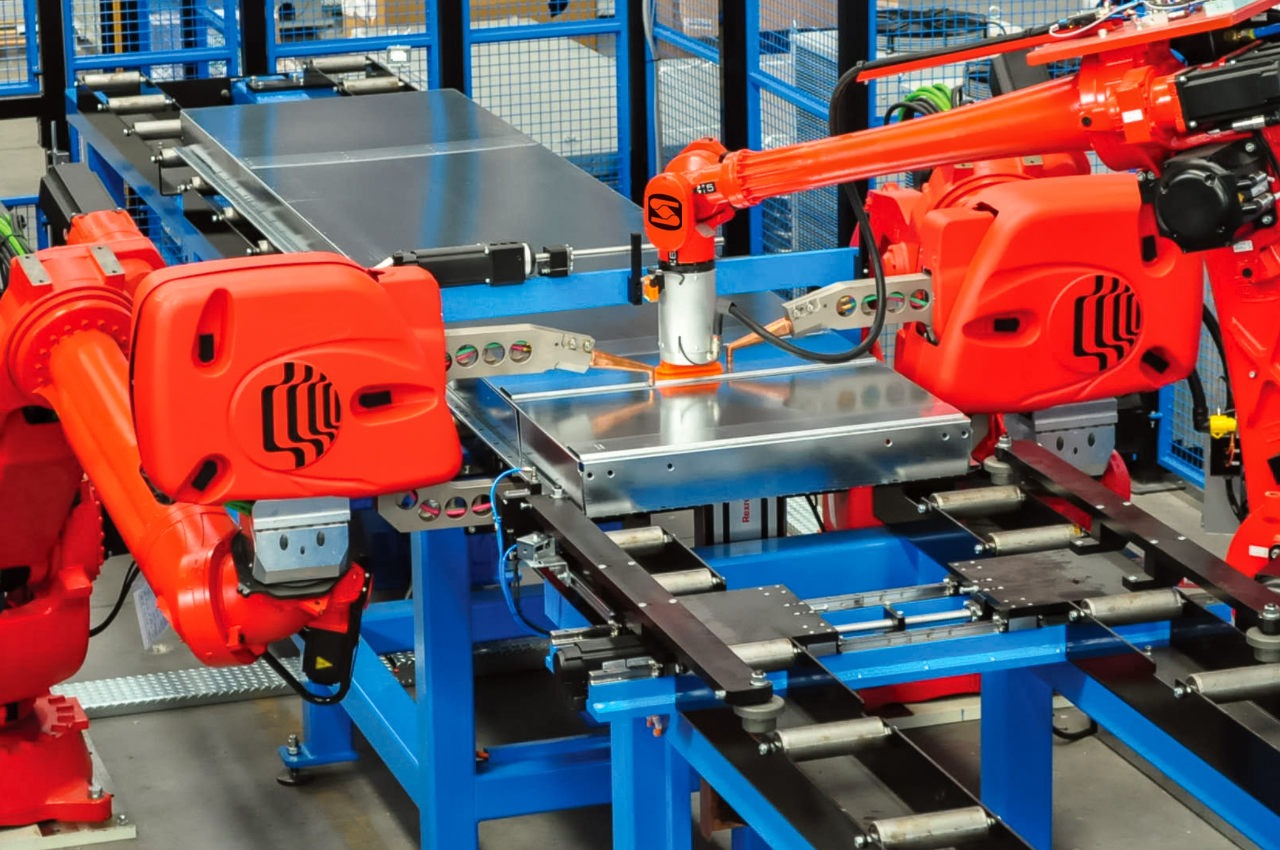

We design and build complete welding lines, with robotic stations that cover all process phases, from feeding of individual components to finished products palletisation.

TURN-KEY SOLUTIONS

From equipment design to stations construction, by way of any secondary processes such as components riveting, screwing or gluing: SIR solutions are a small factory within the factory.

SIMPLIFIED PROGRAMMING

The use of modern software simulators makes program writing quick and safe, optimising the robots’ working area and operation final cycle times.

TOTAL CONTROL

Modern measurement systems for checking workpiece dimensions are combined with three-dimensional inspection of welding beads and spots. Objective, reliable, total quality control.

FUNCTIONAL CHARACTERISTICS

Dedicated Equipment

Functional Integration

Virtual Programming

Metrological and Quality Inspection

APPLICATION AREAS

Automotive

Mechanical

Electromechanical

SOLUTION EXAMPLES

- Wire welding on various types of workpiece.

- Spot welding on various types of workpiece.

- Automotive chassis welding.

- Box beam welding.

- Mining machine component welding.

VIDEO

DOWNLOAD BROCHURE

To download the complete brochure of SIR Welding solutions, enter your data and click “SEND”: you will receive an email with the link to download the PDF file at the address you provided within a few minutes.